The Modular-Lab product family already celebrated its 15th birthday last year. Time to go back to the roots and interview two colleagues who have been involved from the beginning: Kerstin Tautz, design engineer and developer, and Dr. Roger Knopp, chemical developer, both at Eckert & Ziegler Eurotope GmbH – the company behind Modular-Lab. We asked them to share some insights from the very beginning and experiences they made within the last decade working on and with Modular-Lab.

E&Z: Kerstin and Roger, thank you for your time. Could you please give a brief introduction of yourself, your field of action, how long you have been with Eckert & Ziegler and how you joined us?

Kerstin Tautz: I joined Bebig GmbH, another subsidiary of Eckert & Ziegler AG, in 1994, working in the design and development department. Although it was very difficult to find a job as a design engineer, I applied for this position directly after my study, was called for an interview and liked the atmosphere and the professional environment very much. After its foundation in 1995, I joined Eurotope GmbH in 1996 working in a similar department. At this time we were responsible for the development of production lines, special sources and recycling processes for radioactive materials.

Roger Knopp: I started at Eckert & Ziegler Eurotope in 2002, after working at the University of Berkeley in California. I was hired as a radiochemist and was promoted to be a project manager at the end of 2004. For some years I have also been part of the management team. Today I’m heading the chemical development department of both Eckert & Ziegler Eurotope GmbH as well as Eckert & Ziegler Radiopharma GmbH.

E&Z: What was the initial aim of developing Modular-Lab and do you think the development process was simple or complex?

Kerstin Tautz: As in the beginning, we manufactured boxes and production lines and our new aim was to develop a device for process engineering in the radiopharmaceutical business, it was totally different and thus very exciting. Our ambition was to develop a modular system that is flexible, expandable, and hence usable for tracer development as well as for routine production.

It was the first time we repeatedly produced a device and this step coming from custom solutions was different. Thus, I am not sure whether the project was simple or difficult, but definitely, it was and still is a great and fascinating project.

Roger Knopp: I can only agree with this. The market for production sheds was quite unsteady and so was sales and revenue. That is why we tried to develop a niche product with a more regular turnover.

Long story short, we succeeded with Modular-Lab although in the very beginning it was not simple. Some old fashioned chemists would not accept the new modular concept and the system was derided as ‘Lego for chemists’. Nevertheless, when presenting the concept first time at a SNM annual meeting in the USA it was well accepted. About 50 companies showed their interest, which was quite many, especially considering that at this time we did not have more than a video to show. Modular-Lab’s advantage was that the development of tracers was very easy and straightforward.

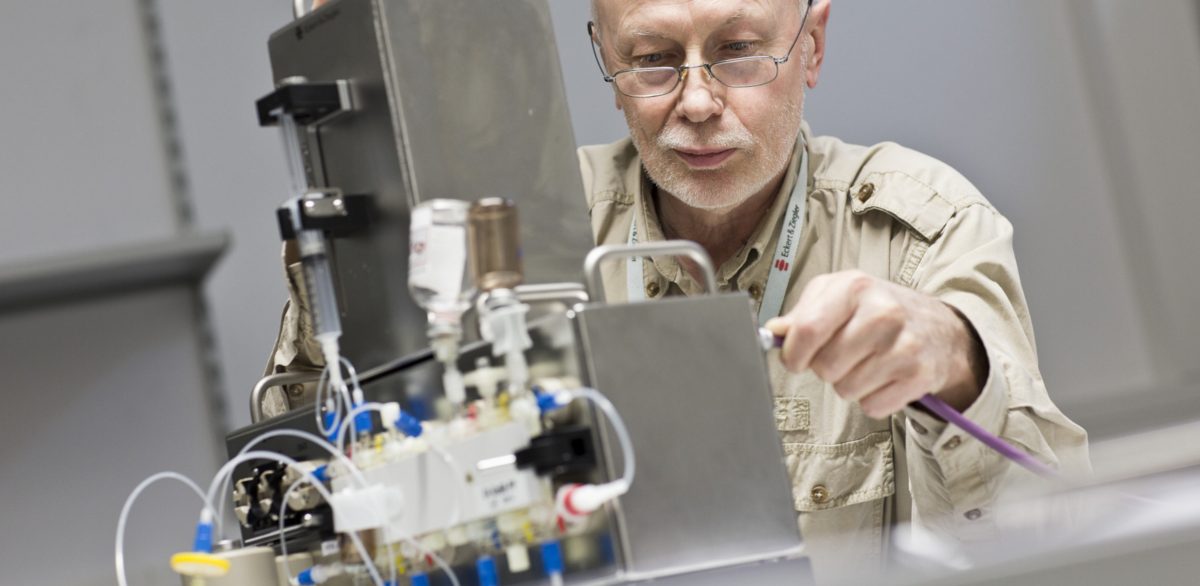

E&Z: Looking at the photo showing the baptism of Modular-Lab in September 2006, what do you feel when realizing that you have been involved from the very beginning?

Kerstin Tautz: It is a great feeling. I do feel proud and happy that I had the chance to give support to the project from the beginning.

Roger Knopp: Of course, I do feel the same. Especially considering that in the beginning nobody knew whether Modular-Lab would be a success or not. Nevertheless, from my point of view the actual milestone was not the baptism, but the first installation and having tested the syntheses successfully on-site – a great feeling!

E&Z: When did you finalize the first system and which tracers were the first synthesized on Modular-Lab?

Kerstin Tautz: Well for us this was a modular design, which could be changed persistently. Thus, I cannot really tell when the first system was finalized.

Roger Knopp: I do remember that the first system was installed at the Tyrolean state hospital (TILAK) and they have been using the system for more than fifteen years now. The two tracers Ga-68 DOTATOC for PET/CT and F-18 FEC (Fluorethylcholine) were the first produced on Modular-Lab.

E&Z: Talking about tracers, what was the most significant tracer that has been developed with Modular-Lab from your point of view? Is there a certain institute/development project that is worth mentioning?

Roger Knopp: There is not really a most significant tracer, but a considerable milestone was that a large pharmaceutical company choose Modular-Lab for their worldwide clinical trial of an Alzheimer tracer. It showed that a global player trusts in Eckert & Ziegler Eurotope GmbH as we complied with their high standards. They had high expectations and visited our facility to audit our processes, which was new to us. Fulfilling these expectations confirmed that our product met all standards for pharmaceutical production (i.e. GAMP4). Furthermore, of course it was great publicity for Modular-Lab. Consequently, our number of sales and the turnover were increasing and getting better and better.

E&Z: In your work with Modular-Lab, is there a certain moment or incident that you kept in memory?

Kerstin Tautz: I like to remember a situation when I just came from a vacation and was told that on the next day I have to travel to Slovenia to support a customer. In general as a design engineer, you do not leave your office for customer visits too often. Therefore, it was great to see how the product was used at a customer site and help the user to operate the system.

Roger Knopp: Already in the first year and short before Christmas, we installed an advanced Modular-Lab system for a clinical trial of a new tracer in Japan, which was quite exciting. Everything was working well although there were some barriers – first of all the language. Then there was the risk that, in case there would have been a failure of the system, it would have taken a lot of time to ship spare parts or replacement modules to Japan. In worst case, we would have had to stay much longer or had to travel back to Berlin and come back days/weeks later. Luckily, all parts functioned properly.

E&Z: Is there an anecdote that is typical for the development and collaboration within the first years?

Roger Knopp: Working and developing Modular-Lab it was always exemplary that we had to develop new features very quickly. Somehow, we always managed these developments in a very short period. As an example, a big customer mentioned during a meeting that they would like to shift their systems to a cassette-based synthesis. As we did not have any cassette-based synthesizers in our product portfolio at this time, we had to create and present a concept within just a few days. Modular-Lab PharmTracer was born. In this period, it was very common to work ten to twelve hours a day.

E&Z: Did you anticipate that Modular-Lab would be that successful?

Kerstin Tautz: Our idea was to develop some kind of Lego-system where the software recognizes whenever a new module is connected. Of course, you can never be sure whether customers and the market accept a product, but it was a great idea and so we were quite confident.

E&Z: What makes Modular-Lab special?

Kerstin Tautz: The software is easy-to-use and the systems are for research and development as well as for routine production. Apart from that we can change, alter or integrate new parts in Modular-Lab at any time, so it stays flexible and extendable, which makes us able to constantly meet new requirements. These features were an advantage from the beginning and gave us a lead in comparison to competitor products.

Roger Knopp: Modular-Lab is easy-to-use and versatile. Software as well as hardware are flexible and easy to understand and the software does not require programming skills.

E&Z: Do you think Modular-Lab will continue its success?

Kerstin Tautz: Our customer is always the center of our attention. Our goal is to provide them a wide range of individual, valuable and innovative solutions for their daily work – from laboratory equipment to radiopharmaceutical products. With our great team consisting of radiochemists, electronics technicians, mechanical and software engineers we are able to convert ideas coming from the market into innovative products. Our creativity and energy will help us to continue the successful development of new products in the future.

Roger Knopp: I definitely agree with Kerstin. Customers’ requirements steadily change and it is our duty and aim to steadily improve and to understand our customer’s needs. Currently the market asks for simple production solutions. Referring to Modular-Lab eazy, we already developed a product meeting these challenges. Thus, I think we will continue to be successful.

E&Z: Thank you for these insights and sharing your experiences.