Almost fifteen years ago, the PET Centre at Kings’s College London, UK bought the 10th Eckert & Ziegler Modular-Lab synthesis system. It was a tube-based Modular-Lab Standard for research and development. Elham Fakhri from Imaging Equipment, our former Eckert & Ziegler distributor in the UK visited Dr. Robin Fortt and Prof. Antony Gee to ask a couple of questions regarding their experiences with Modular-Lab and new projects in their pipeline.

Elham Fakhri: Good morning Tony. Could you give a brief introduction for yourself and what your role is within the PET centre? Following that, what is your experience with Eckert & Ziegler?

Antony Gee: I am head of PET-Chemistry at Kings College London. We have a pipeline of novel-tracers that we are introducing for preclinical and translational studies into humans. For example this week: we have performed the first human studies of the novel tracer [18F]BF4, recently developed by the KCL team. To be able to develop and evaluate novel tracers like this, we need flexible radiotracer synthesis systems to give us the scope to optimize and change the labeling processes. The Eckert & Ziegler system does this very well, and helped us to get this new tracer for the the first time into man. We are delighted to continue our work with Eckert & Ziegler modules.

Elham Fakhri: Thank you very much Tony and good morning Robin. Could you also please briefly introduce yourself and tell us about your experience within the field of nuclear medicine and PET/CT. Furthermore, we would like to get an idea of what you’ve been using your Modular-Lab Standard for and understand what happens in the KCL PET Imaging Centre in general.

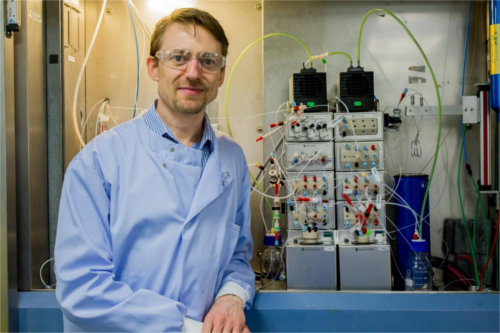

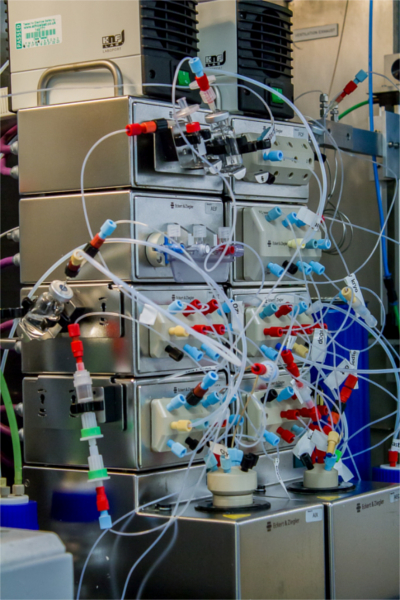

Robin Fortt: I’m the development and instrumentation manager within the KCL St. Thomas’ PET centre. I’ve been here for several years and during that time we’ve been using the Eckert & Ziegler Modular-Lab system for a variety of tracers. Most recently, as of Friday we performed the first in man synthesis and injection of Tetrafluoroborate, an 18F labeled tracer that was developed here at Kings. We are also using the same system simultaneously for [11C]acetate syntheses. So we have the combination of well-established syntheses, such as acetate, and novel 18F tracers, such as BF4; two different PET isotopes, one synthesis system. Because of the modular way in which the Modular-Lab is constructed we’re able to effectively divide the system in two and so none of the system’s components are shared. But we have one EC-cabinet, one synthesis laptop and it only takes up the space of one hot cell. That modularity is very important for us. The ability to customize the synthesis platform to do whatever we want and at any time, when we decide we need a new module that we don’t have, it’s a simple matter of just buying it, plugging it in and thus adding functionality that we didn’t have previously. All for a relatively small expenditure without having to buy an entirely new synthesis system.

Elham Fakhri: Could you please give a short insight in the work of the KCL PET imaging centre at St. Thomas? Please name three to four milestones.

Robin Fortt: The PET centre was established almost 30 years ago now, in 1992-1993. We currently are producing tracers in house for the scanning of up to 5000 patients per year. The vast majority of those are FDG, produced in-house. The non-FDG tracers are either synthesized on a Carbon-11 synthesis system or on the Eckert & Ziegler Modular-Lab. We have 2 Modular-Labs. The first was bought about 15 years ago. We’ve used that most recently for the synthesis of BF4 and Acetate, as well as for the synthesis of 18F labelled FLT, FET and FEC. Our most recent E&Z-acquisition was EC-285. That was over eight years ago. We’ve used that mostly for the clinical production of 18F-fallypride and we’re just about to validate the synthesis of 18F-FPEB, which is a project that we’ve been working on for a while. In the literature the 18F-FPEB synthesis typically yields 4-5 %. There are only about 5 PET centres in the world making it (in the literature at least). And we’re now achieving yields of around 14-15 % with our Modular-Lab, so we are very happy with the way it performs. In terms of recent milestones, a new facility, including two GMP labs, a dedicated R&D lab, a dedicated QC lab and unshielded cyclotron and vault has succesfully been constructed.

Elham Fakhri: What are the advantages of the Modular-Lab system? You briefly mentioned the modularity, is there anything else that you like about the Modular-Lab?

Robin Fortt: The modularity is the key importance and the said ability to upgrade the system. Traditionally, when you buy a synthesis system, there is no option of integrating alternative features directly into software.

Two examples: You want to add a syringe drive module to an automated synthesis platform which does not have one. Attaching it via plumbing is not difficult. But how can you integrate the control of the module into the software of a system which is designed not to take it? How do you go about controlling it? None of that is an issue with the Modular-Lab Standard. A synthesis platform has three syringe drivers. If I want five syringe drivers on a Modular-Lab Standard, there is nothing to stop me. I am not limited to the number. So that gives me an amazing amount of flexibility.

Another example: When you’re trying to develop new tracers that have never been produced before and where no fixed ‘recipe’ has been described for you to follow, the ability to just add-on extra functionality and extra components is key.

Another feature that is also very nice is the fact that we can arrange the valves, the tubing and the plumbing in any way we like through the Modular-Lab software. We can drag and drop components from the Modular-Lab library, both in the graphical user interface and in creating macros, and arrange the tubing in any way that we desire without any limitations. We’re not forced to go from valve one through valve two to get to valve three. I can drag and drop as I like and plumb as I like. That gives us an amazing amount of flexibility.

Elham Fakhri: The UK is one of the strictest countries in terms of regulations. How has Eckert & Ziegler been efficient in regards to that?

Robin Fortt: Well, the fact that the software is GAMP 5 and 21 CFR part 11 compliant goes a long way to satisfy our regulators. Batch reports are generated automatically in PDF format, they are non-editable, the software captures the times of each step of the synthesis, the user’s name and details and any interference by the operator, such as if you have to pause the program or skip a step. I get reliable real time data on temperature or radioactivity. In the past life I used to build my own systems from scratch, from valves and wire and the amount of validation that I always had to go through to satisfy our QA department was extreme. The fact that the Modular-Lab software has all the regulatory paper work in place and is inherently build into the system makes my life very easy from the development as well as from the troubleshooting perspective. I can go back and I get the trending or look at steps that have been skipped or modified by the operator. Because of the software’s 21 CFR and GAMP 5 conformity the regulatory side very easy as well. Basically they see the Modular-Lab Standard and they’re happy, so they don’t dig deeper.

Elham Fakhri: Where do you see your PET department going into in roughly 10 years time?

Robin Fortt: Well, our current lab is nearly 30 years old, it has four hot cells and it’s been very much about supplying FDG to 20 patients a day and that has been our core business. We have research studies, but it’s at most one patient a day or a couple of different non-FDG tracers per week. With the expansion and the new facility we’re going to massively expand both our portfolio of tracers and the number of research studies we will be entering into. I have a list of probably 10 new tracers both a combination of existing tracers that have already been well developed and established within the literature that our clinicians want to apply to new disease models as well as entirely new tracers never before been used in man. The expansion of the research and development aspect of the PET-centre is going to be the main focus for the next 10 years.

Elham Fakhri: How people are working with the Modular-Lab systems?

Robin Fortt: Currently there are two extremely talented development chemists working for me – Frazer Twyman and Stefan Hader. They are both working on projects for development and translation into man. Within the core production team we have two more, Fabio Rinaldi and Neria Ossoulyan. They’re working on the clinical 18F-fallypride work and clinical 18F-BF4. Then at the same time we use spare valves that aren’t currently dedicated to the acetate or the 18F-BF4 to do simple research projects with the PhD student Carlotta Taddei and Post-Doc Salvatore Bongarzone. So I guess we have a team of six or seven people currently working on the two different Modular-Labs, split three ways – four ways really and that’s the flexibility the Modular-Lab gives us. We don’t have to worry about a PhD student playing with the E&Z, because she’s got her own dedicated valves-set that is not used in the clinical, it’s not used in the IMP -synthesis . So we’re happy for her to do whatever she wants. She blocks a valve or she has a leak – doesn’t bother me because it’s completely separate and that’s really useful.

Elham Fakhri: Is there anything being developed on the preclinical system at the moment with you guys here at KCL?

Robin Fortt: The most exciting research work coming out of that at the moment is Carlotta and Salvatore’s work. They’re doing a carbon dioxide to carbon monoxide conversion on the Modular-Lab which is mediated with silane species and they are also doing carbonylations with the CO, to make [11C]amides and [11C]esters. Furthermore they’re working on carboxylations, with CO2 to produce [11C]carboxylic acids, [11C]ureas and other carbonyl-containing compounds. That’s all very exciting, when that’s being applied to the new tracers coming through the pipeline we’ll see how they look in the preclinical environment. So that’s at the very early stage and then we’ve got the very late state. For 18F-FPEB we’re doing some animal metabolite work to see how the metabolite profiles look in the preclinical environment before we go into man.

Elham Fakhri: I know you’ve been having Eckert & Ziegler Equipment for roughly 15 years, how has that experience been with the service they have provided?

Robin Fortt: Well in general we find the modules very reliable; I mean we have five of the four valve modules that are nearly ten years old. We don’t have any trouble with blocked tubes, we don’t have any trouble with leaks and we don’t have any trouble with things wearing out. Day-to-day they are used quite heavily in a range of different chemical environments. We generate solids accidentally, we put harsh acids through them and generally they are very robust. Paul Smith the engineer from Imaging Equipment comes to do the service but generally he doesn’t have all that many things to worry about other than just to giving a spring clean. Paul is very knowledgeable and when we do have trouble he’s always got plenty of good ideas and suggestions how we can sort our problems over the phone without him to come in, so that’s very useful. When we have had issues with a module we’ve been sending it back to Eckert & Ziegler and Imaging Equipment has been finding us with a loan module, so we’ve never been without a module for more than a couple of days.

I look forward very much in the future to seeing new developments in the software and modifications to the hardware to make the Eckert & Ziegler system even more broadly applicable, flexible and useful for the new PET-centre going forwards.

Elham Fakhri: That ends our interview for today, thank you very much.

The interview was originally conducted at King’s College London PET Centre at St. Thomas Hospital, UK on March 1, 2016. Dates and timelines have been adjusted to fit the re-release in 2022.