In industry and research institutions

For the use, examination and testing of radioactive materials from the industry e.g. nuclear power plants, hot cell complexes must fulfill special requirements. This includes customized solutions for the handling of large sizes, different shapes as well as the implementation of unique testing and handling instruments.

Key Features

The new experimental facilities bring the research of irradiated materials to the next level, by providing substantial remote handling capabilities in the hot cell island.

ATS Ydintekniikka, 45(3), 42-45.

Dr. Wade Karlsen

Research Team Leader, Nuclear reactor materials, VTT

Eckert & Ziegler offers fully customized turn-key solutions for the safe handling of radioactive materials in the industrial context. The facilities are tailored to the range of devices used for customer processes and can be adapted to different sizes and shapes, e.g. in the testing of material from nuclear power plants.

Challenges, such as the operation within special ambient conditions (e.g. underpressure) or the work within different levels using lifts and cranes will be realized to accommodate pre-defined processes. This also includes the provision and installation of specialized instruments for manipulation and accurate testing of material. In this context Eckert & Ziegler uses their long-term experience to offer consulting for optimization of procedures and to invent and implement customized features to facilitate daily work.

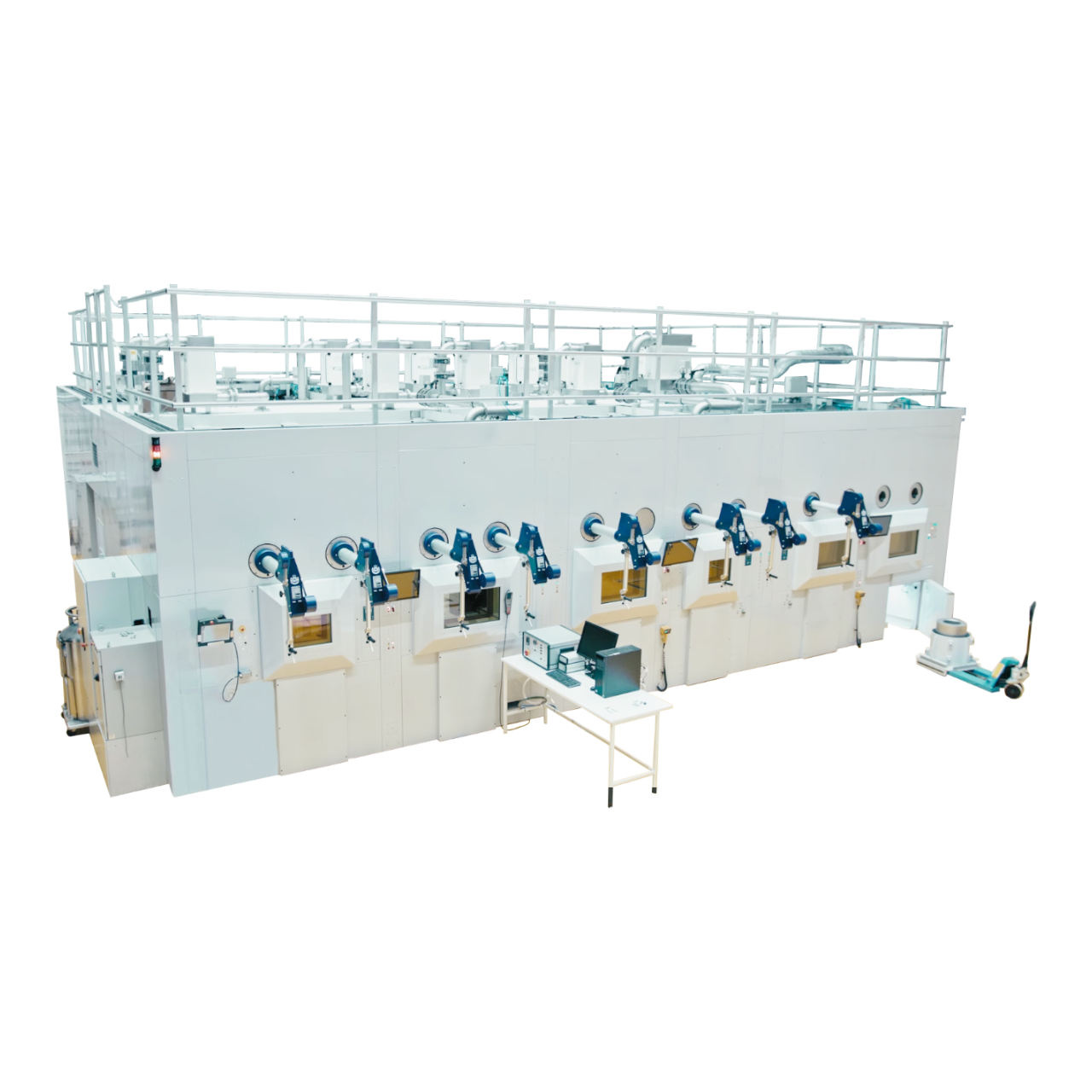

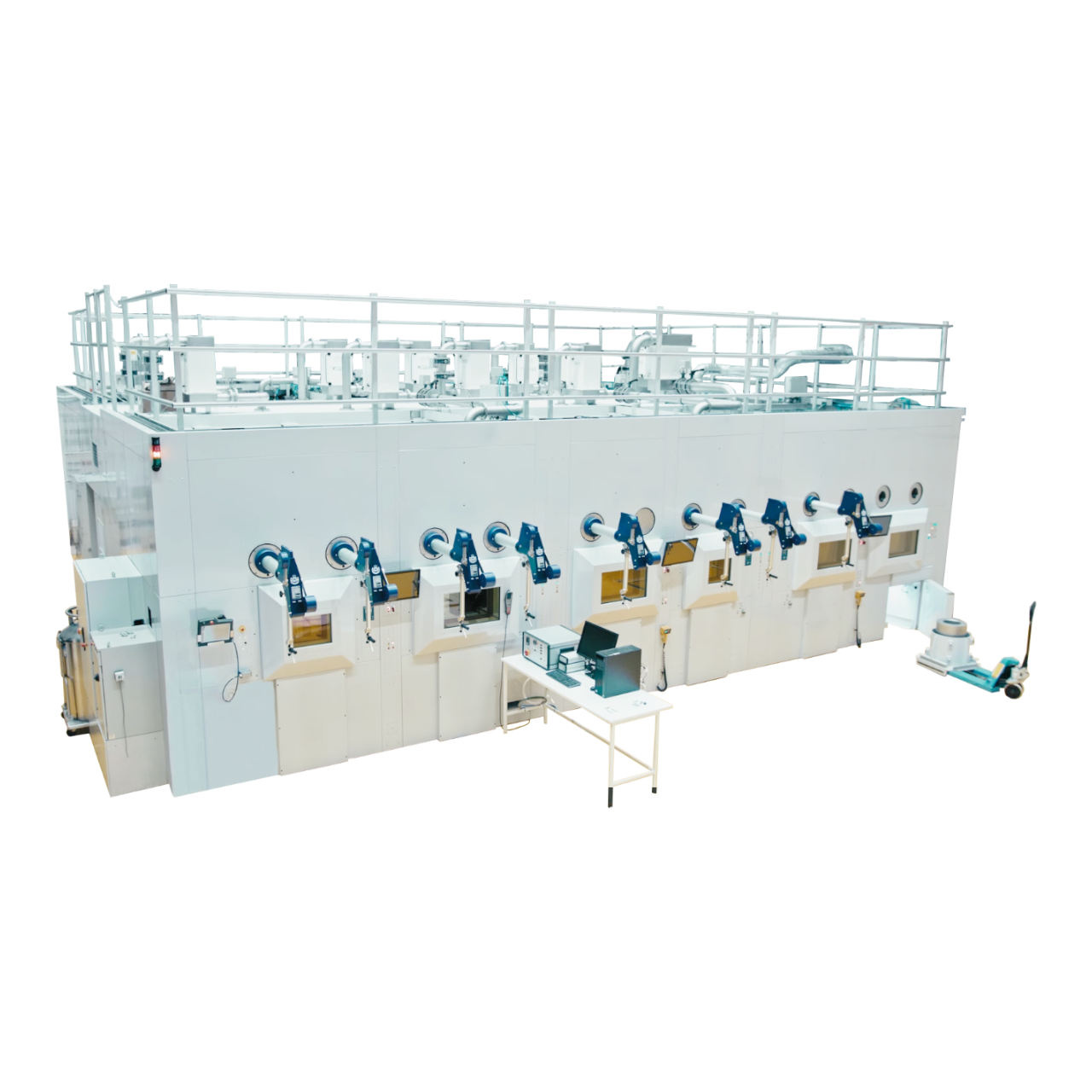

Hot Cell Complex at VTT Technical Research Centre of Finland

In 2017 Eckert & Ziegler finalized the engineering, design and manufacture of a huge complex consisting of 11 state-of-the-art hot cells for the multi-property testing of radioactive materials at VTT in Finland. The lead shielding was as thick as 250 mm and most hot cells were equipped with master-slave manipulators and windows from lead glass in customer specific standards.

A challenge was the fabrication of steel boxes that can operate with an underpressure. Besides, VTT requested a rear access area for maintenance with sealed doors and glove ports. The insertion of radioactive materials in various sizes and shapes from shielded transport casks was realized with different docking ports through a reception cell in the basement of the facility. After transfer to the main working area with a lift a conveyor system transports the material between the testing locations.

Testing procedures include accurate cutting with electric discharge machining, reconstitution processes, electron beam welding, fracture toughness testing in different temperatures monitored by laser extensometry, impact testing and more. In addition, in the metallography specimens can be prepared for light microscopy, fractography and analytical transmission electron microscopy.

To get a better impression, please watch the following video:

Process and Services

Eckert & Ziegler is committed to deliver the best possible solution for your process and project. Therefore, we offer several services for the arrangement of facilities inside new or present premises together with our hot cell equipment. These include consulting and support for the determination of space, clean room, auxiliary and special additional requirements as well as material and personnel flow schemes, effectivity testing, measurement and customization of shielding and lead glass windows for your application.

Furthermore, we provide mock-ups for testing the functional handling and special combined transport and docking solutions for input and output of radioactive material into the hot cell. A dedicated project manager will support you from first contact, via design, installation and training to service and extension of your facility.

Publications

Product specific questions?

Isotope Technologies

Dresden GmbH

Rossendorfer Ring 42

01328 Dresden

Germany