for the operation of automated radiosynthesis modules

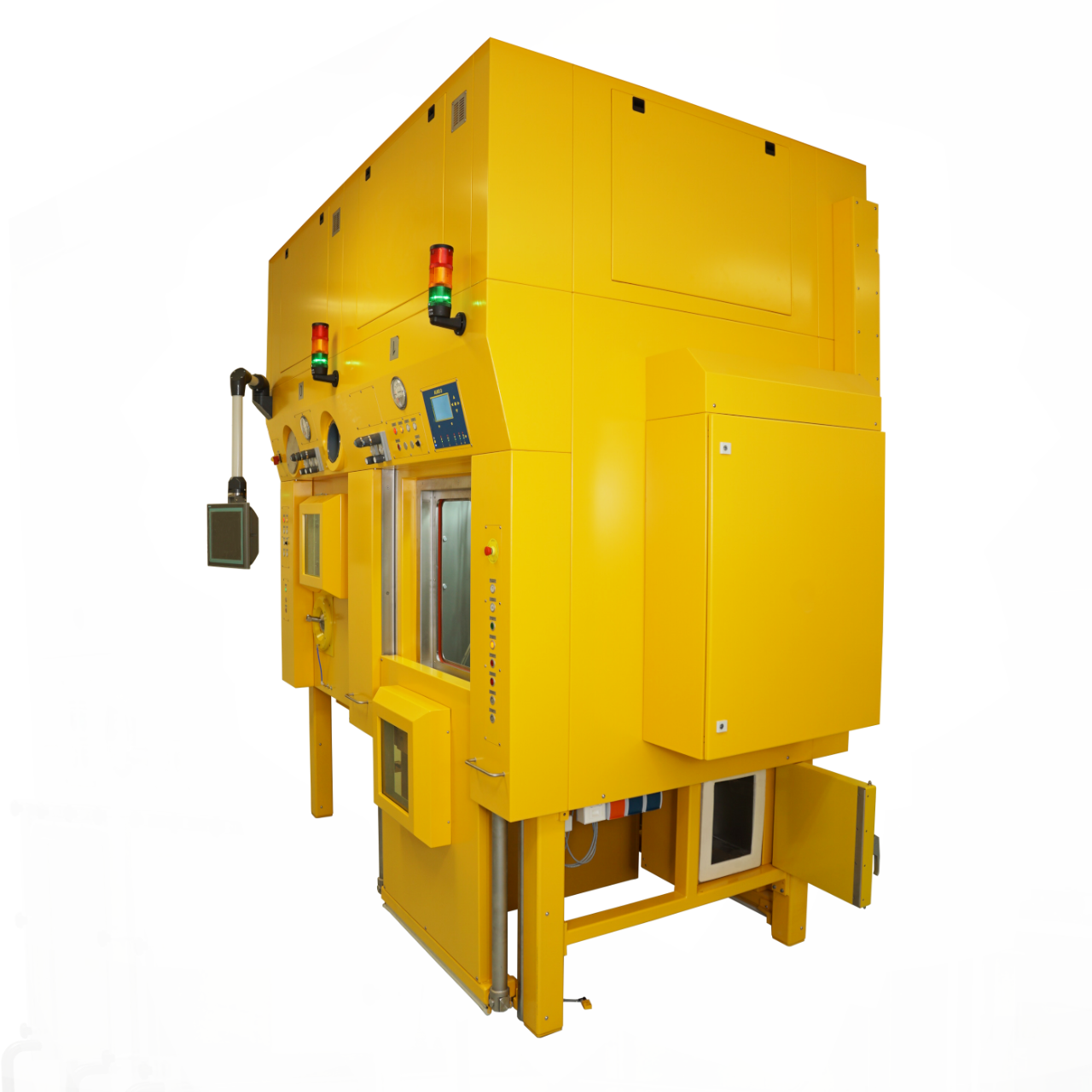

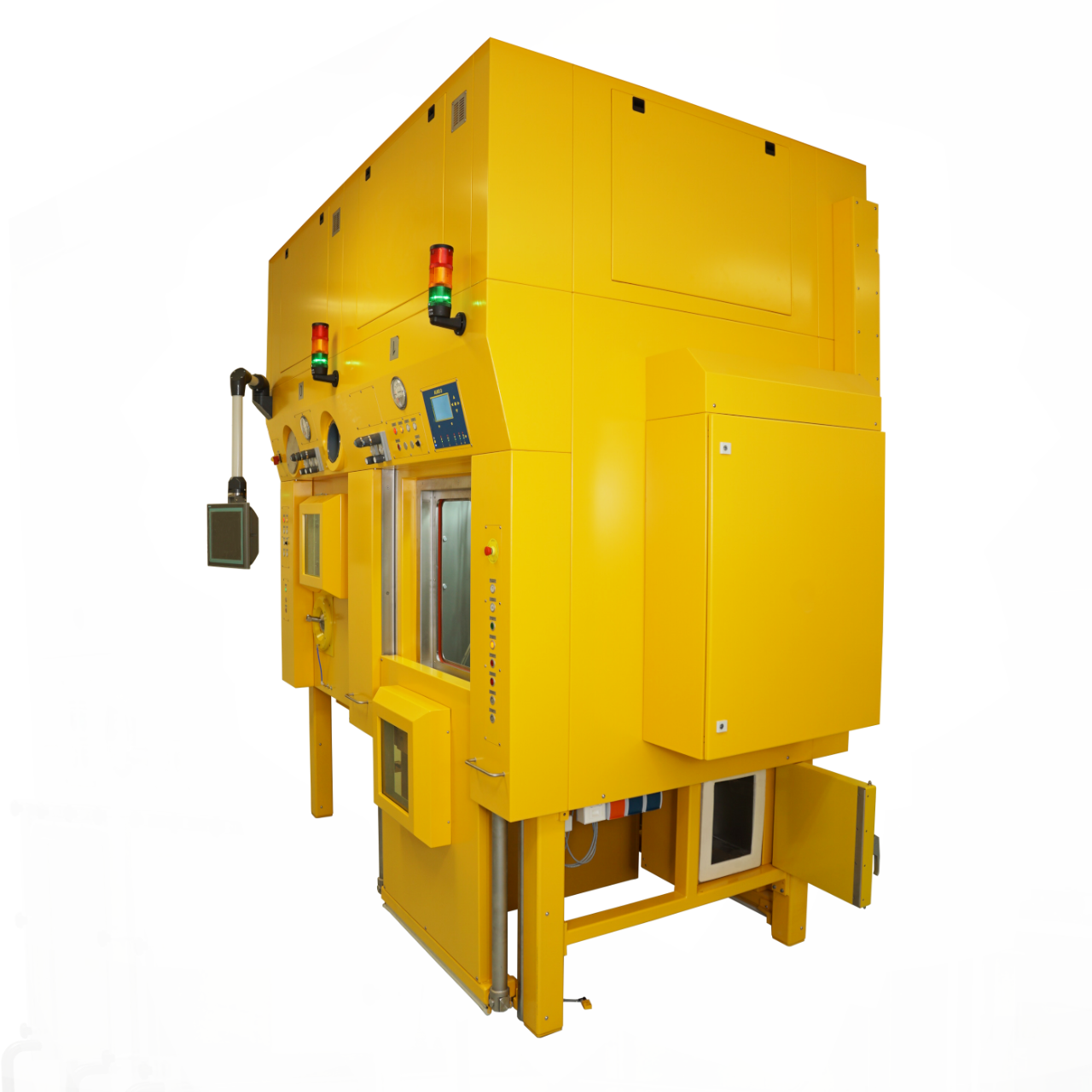

The synthesis cells are designed for the operation of radiosynthesis modules in routine production but can also be adapted for research and other purposes. Designed to comply with GMP regulations they ensure the highest quality of production conditions. All synthesis cells can be uniquely modified according to customer’s requirements.

Key Features

The construction of the synthesis cells ensures GMP-compliant production under grade C conditions. There are four major types that differ in size and weight:

|

Inner dimensions (WxDxH) |

Outer dimensions (WxD) |

Height |

Weight kg |

|

|

Type I |

700x560x775 mm |

920×850 mm |

3000 mm |

approx. 3,500 |

|

Type II |

700x640x775 mm |

920×930 mm |

3000 mm |

approx. 3,800 |

|

Type III |

850x640x775 mm |

1070×930 mm |

3000 mm |

approx. 4,500 |

|

Type IV |

700x500x610 mm |

920×770 mm |

3000 mm |

approx. 6,000 |

The standard model consists of a stainless-steel cell and 75 mm lead shielding. A shielded door with an optional lead glass window is implemented at the front side for easy access to the synthesis module. All types can be customized to the client’s individual process requirements and physical conditions of the used materials and radionuclides.

Special Solutions and Optional Features

We offer various additions and options for your synthesis cell to further facilitate your daily work and processes. These include:

Process and Services

Eckert & Ziegler is committed to deliver the best possible solution for your process and project. Therefore, we offer several services for the arrangement of facilities inside new or present premises together with our hot cell equipment. These include consulting and support for the determination of space, clean room, auxiliary and special additional requirements as well as material and personnel flow schemes, effectivity testing, measurement and customization of shielding and lead glass windows for your application.

Furthermore, we provide mock-ups for testing the functional handling and special combined transport and docking solutions for input and output of radioactive material into the hot cell. A dedicated project manager will support you from first contact, via design, installation and training to service and extension of your facility.

Product specific questions?

Isotope Technologies

Dresden GmbH

Rossendorfer Ring 42

01328 Dresden

Germany